Because the mobility and EV trade converges round a seemingly restricted array of battery sizes and simply three type elements, California-based Sakuu is suggesting a really completely different, seemingly infinite vary of potentialities—like future cells sized and formed for merchandise.

The manufacturing hook behind this proposition is 3D printing. Whereas there have been a couple of makes an attempt at 3D batteries earlier than, Sakuu claims that as of December 2022 it’s the primary “firm of report to 3D-print totally purposeful batteries in {custom} sizes and shapes with patterned openings for thermal administration in a totally dry course of.”

The corporate says that it’s on monitor to make printed batteries at scale for mobility, aerospace, EVs, and vitality storage, amongst different makes use of—and the profit from first look is that the cell design can comply with the product design, slightly than vice versa.

It doesn’t say what the vitality density of those first cells is, however it guarantees spectacular figures by quantity. It claims “expectations are to attain excessive vitality density at 800–1000 Wh/L.” That’s certainly larger than the present technology of lithium-ion cells utilized in EVs—and even what’s been focused by Panasonic, as an example, by 2030.

Flexibility away from skateboards

Within the not-too-distant future, such custom-shaped cells would possibly carry alternatives for electrical car engineers and designers who at this time have converged on the “skateboard” battery format—physique over a skinny battery brick—because the package deal with the least compromise.

Such batteries would possibly permit sure parts of the physique construction itself in EVs to be crammed with uniquely formed battery cells slightly than left empty, altogether comprising a mass-less battery of types, and liberating up passenger-car and coupe our bodies to be decrease, leaner, and sleeker.

Within the electrical automobile realm, that would imply that designers and engineers would possibly have the ability to curb the inherent compromises of a skateboard.

Sakuu 3D-printed battery cells

With the announcement, Sakuu has proven an indication single-layer cell, which it may then stack with many others, connecting them in collection or parallel as wanted, to type a pack. Two holes present the place coolant passages would run inside a pack.

Totally different course of than all of the battery factories

Sakuu makes use of a dry cathode course of and a single platform printing machine, and it emphasizes that this isn’t a moist display printing course of, which makes use of extra vitality to take away solvents and might be unreliable.

Neither is it something just like the roll-to-roll course of that’s used to make most battery sorts. The corporate, in what’s additionally referred to as additive manufacturing, constructs super-thin layers at a time, making use of a number of supplies as a part of the identical layer.

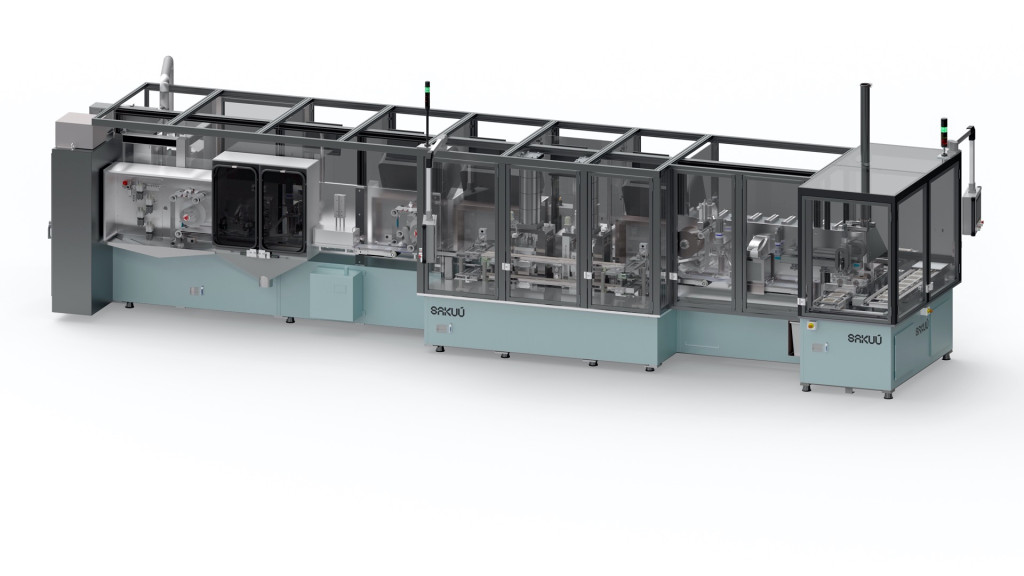

Sakuu, which was based in 2016 as KeraCel and was rebranded in 2021, opened a 79,000-square-foot improvement facility for its manufacturing platform in San Jose. It guarantees “world class vitality and energy densities at manufacturing speeds corresponding to the very best roll-to-roll manufacturing tools,” and it claims it has the one recognized manufacturing resolution to provide solid-state batteries at business scale.

The corporate goals to license its battery chemistries in addition to promote its manufacturing platform, which it desires to see used to make 200 gigawatt-hours of cells by 2030 via “international accomplice gigafactories.”

Porsche Consulting has mentioned that it’s going to design the battery maker’s 3D-printing gigafactory for mass manufacturing of the tech. Sakuu confirmed to Inexperienced Automobile Experiences that the renderings listed below are of pilot manufacturing tools already in use.

Sakuu 3D-printed battery cells

Rushing up stable state?

The agency’s approach may assist spur the manufacturing of solid-state cells sooner, and it would probably allow larger vitality densities, by permitting thinner battery cell layers, in order to suit extra in a given format and area.

There are various different theoretical benefits of solid-state batteries, together with quicker charging and better efficiency, in addition to, relying on how they progress as they transfer to mass manufacturing, larger sturdiness and fewer degradation.

Within the solid-state subject, there’s no scarcity of rivals. Along with the battery institution, a bunch of corporations together with Factorial, StoreDot, and QuantumScape declare to have a bonus on this battery revolution. Nissan can also be one in every of a number of automakers engaged on its personal solid-state cells. It’s additionally aiming for a dry course of, however with a conventional layered strategy to the cells, albeit with some supplies tips corresponding to a meshlike binding between lively materials and stable electrolyte.

Sakuu at the moment has two battery-chemistry traces in improvement, a lithium-metal, and an all-solid-state lithium-metal. Whereas it gained’t disclose different particulars relating to these chemistries, it says that each use the corporate’s 3D-printing-based manufacturing strategy.

Sakuu 3D-printed battery cells

3D printing methods have numerous makes use of within the automotive realm, from reprinting unavailable components for older Tesla Roadsters, to the creation of electrical motors product of 3D-printed components, to a complete Cadillac Celestiq EV flagship made attainable with 3D printing methods.

From an environmental angle, there could also be some further benefits. 3D printing tends to make use of much less materials versus conventional manufacturing strategies, by the very nature of the additive course of it makes use of. It additionally usually requires much less vitality. With 3D printing, targets for price, the provision chain, and carbon footprint is likely to be met sooner.